Timing Belt Handling & Storage

Downloadable/printable Timing Belt Handling and Storage (.pdf)

Timing Belt Handling

Timing belts are extremely durable and will give a long life in a properly designed drive. However, improper handling of the timing belt before or during installation can result in dramatically shortened service life. The timing belt's tensile cords are designed to carry large loads in tension but not compression. Compression causes damage to the tensile cords of the timing belt and can also lead to adhesion problems. Handling situations that can cause compression in tensile cord include aggressive bending and twisting.

Timing belts are extremely durable and will give a long life in a properly designed drive. However, improper handling of the timing belt before or during installation can result in dramatically shortened service life. The timing belt's tensile cords are designed to carry large loads in tension but not compression. Compression causes damage to the tensile cords of the timing belt and can also lead to adhesion problems. Handling situations that can cause compression in tensile cord include aggressive bending and twisting.

Examples of this are:

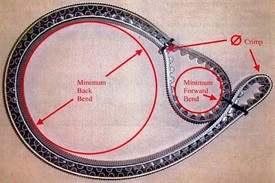

Crimping the Timing Belt

Crimping of the timing belt occurs when enough bending pressure is put on the belt in a small radius so that a permanent "set" is formed in the timing belt. The timing belt will often take on the outline of a fish head. Crimping damages the tensile cords and will result in premature failure. DO NOT crimp timing belts.

Forward Bending the Timing Belt

When handling timing belts, forward bends (bends that cause the teeth to come together) should be limited to the following minimum diameter for the given belt pitch.

- 8mm Belt Pitch - 2 1/4" Diameter

- 14mm Belt Pitch - 5" Diameter

DO NOT forward bend timing belts tighter than the diameters shown above

Back Bending the Timing Belt

When handling timing belts, back bends (bends that spread the teeth apart) should be limited to the following minimum diameter for the given belt pitch.

- 8mm Belt Pitch - 5" Diameter

- 14mm Belt Pitch - 10" Diameter

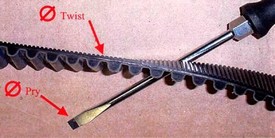

Twisting the Timing Belt

DO NOT twist the timing belt as shown in the picture. This includes coiling the timing belt to make it smaller for packaging.

DO NOT twist the timing belt as shown in the picture. This includes coiling the timing belt to make it smaller for packaging.

Timing Belt Storage

Timing belts should be stored in a cool and dry environment with no direct sunlight.

Timing belt quality will not change significantly within eight (8) years of proper storage, as outlined in Rubber Manufacturers Technical Bulletin IP-3-4. A proper storage environment has been defined as an ambient temperature of less than 85°F and relative humidity of less than 70%. Service life is expected to decrease 10% per year for each year of storage beyond eight (8) years. In addition, storage limitation decreases by 50% for each 15°F increase in storage temperature. Storage temperatures should never exceed 115°F.

Typically timing belts are hung from pins or saddles, or “nested” inside one another. Pfeifer Industries recommends that you try to AVOID nesting the belts at all costs; particularly in the smaller length timing belts (i.e. 8M-640mm, 8M-720, 8M-800, 8M-896). Nesting smaller belts creates small radii which could DAMAGE the tensile members in the belts. Timing belts should not be bent tighter than the smallest recommended sprocket diameter for that cross section on the inside (2-1/4” for 8mm Pitch and 5” for 14mm pitch). This was particular evident with the Gates PolyChain® GT timing belts where you could bend the belts and actually hear the tensile members cracking inside the belt, thus rendering it useless.

Additionally AVOID the following:

- DO NOT store timing belts on the floor unless a suitable container is provided. They may be susceptible to water leaks or moisture or otherwise damaged due to traffic

- DO NOT store timing belts near windows which may permit exposure to sunlight or moisture.

- DO NOT store timing belts near radiators or heaters or in the airflow from heating devices.

- DO NOT store in areas near evaporating solvents or other chemicals are present in the atmosphere.

- DO NOT store in high ozone environments

- DO NOT induce sharp bends or crimp the timing belt

- DO NOT cause distortion or excess weight on the timing belt