Timing Belt - Installation

The following is an installation guideline designed to combat problems resulting from improper installation of timing belt drives.

Click here to download a PDF for more information.

1) Loosen Motor

Check to make sure that the motor is OFF, a lock-out/ tag-out procedure should be in place to prevent accidentally motor start-ups. Loosen motor mounting bolts. Move motor until existing timing belt is slack and can be removed without prying.

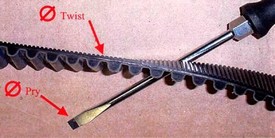

NEVER PRY OFF A TIMING BELT, PRYING THE TIMING BELT WILL DAMAGE THE TIMING BELT PULLEYS TEETH AND/OR FLANGE THAT YOU ARE LEVERAGING AGAINST.

2) Remove Old Timing Belt

Remove old timing belt and check the timing belt for unusual wear. Excessive wear may indicate problems with the drive design or preventive maintenance program.

3) Select Correct Replacement Timing Belt

Selection of the correct timing belt replacement is critical. A timing belts tooth shape (timing belt tooth profile) are not uniformly standardized among the various timing belt manufacturers. However, as there are many instances where there is drop in compatibility between the various manufacturers there are just as many instances where they are not compatibility. If you are unsure of what timing belt you have or how to identify the timing belt needed for your application. Please refer to our guide titled Timing Belt Identification and Timing Belt Replacement.

Caution must be taken if any of the timing belt pulleys have been replaced with a timing belt pulley containing a different number of teeth. Besides the ratio being changed the center to center distance requirements will have changed for the timing belt also. Make sure that you are using the right length timing belt.

Caution must be taken if any of the timing belt pulleys have been replaced with a timing belt pulley containing a different number of teeth. Besides the ratio being changed the center to center distance requirements will have changed for the timing belt also. Make sure that you are using the right length timing belt.

NEVER FORCE ON A TIMING BELT THAT WILL JUST FIT, PRYING THE TIMING BELT ON WILL CRACK THE TENSILE CORD MEMBERS INSIDE THE TIMING BELT LEADING TO PREMATURE BELT FAILURE.

4) Clean the Timing Belt Pulleys

Timing belt pulleys may be cleaned by wiping with a rag slightly dampened with a light, non-volatile solvent. Soaking or brushing the solvent on the timing belt is not advisable. Obviously, sanding or scraping the timing belt or timing belt pulley with a sharp object to remove grease or debris is not recommended. Timing belts must be dry before using on a drive.

5) Inspect the Timing Belt Pulleys

Inspect the timing belt pulleys for unusual or excessive wear.

6) Proper Alignment

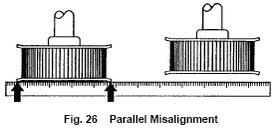

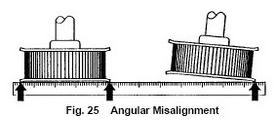

The two main types of drive misalignment are ANGULAR and PARALLEL as illustrated in the below pictures.

Timing belt drive alignment is one of the most common causes of drive performance problems. Misaligned drives can show symptoms such as:

- high timing belt tracking forces

- uneven timing belt tooth wear

- high noise levels

- uneven load distribution

- timing belt tensile cord failure

Parallel Misalignment

Parallel misalignment is where the driver and driven shafts are parallel but the driver and driven timing belt pulleys on these shafts lie in different planes.

Angular Misalignment

Angular misalignment is where the driver and driven shafts are not parallel. Resulting in uneven loading of the timing belt tensile cords. The tensile cords on the high tension side are often overloaded which may cause edge cord failure which would be transmitted across the width of the timing belt. This misalignment also results in high timing belt tracking forces which causes excessive timing belt edge wear.

ANY DEGREE OF MISALIGNMENT WILL RESULT IN SOME REDUCTION OF BELT LIFE, WHICH IS NOT ACCOUNTED FOR IN THE NORMAL DRIVE DESIGN PROCEDURE. MISALIGNMENT OF TIMING BELT DRIVES SHOULD BE LESS THAN 1/4° DEGREE OR 1/16 PER FOOT OF LINEAR DISTANCE.

A simple procedure to check misalignment (both parallel and angular) is by using a straightedge (ruler) to check alignment as the previous illustration shows. The straightedge should be long enough to span the distance between the two outside edges of the timing belt pulley faces. Lay the ruler across the face of the two timing belt pulleys, if the two timing belt pulley faces are not even with the straightedge than you have parallel misalignment. Another possibility with using the straightedge method would be that one of the timing belt pulley faces would lay flush with the straightedge while the other timing belt pulley would have only one edge of the timing belt pulley face touching the straightedge. In this scenario an angular misalignment would be represented. This process should then be reversed using the opposite timing belt pulley as a starting point so that the total effect of the misalignment is taken into account. Remember to account for differences in the timing belt pulley edge thickness dimension and also the degree of bend on the timing belt pulley flanges.

Another procedure for checking for parallel misalignment would be to accurately measure the distance between the shafts at three (3) points along the shaft. The distance between the shafts should be the same at all three (3) points.

ALSO MAKE SURE THAT THE SHAFTS ARE RIGIDLY MOUNTED. SHAFTS SHOULD NOT DEFLECT WHEN THE TIMING BELT IS TENSIONED. A NON-RIGID MOUNT CAUSES VARIATION IN THE CENTER TO CENTER DISTANCES RESULTING IN TIMING BELT SLACK. THIS TIMING BELT SLACK COULD LEAD TO A RATCHETING OF TEETH ON THE TIMING BELT PULLEY - ESPECIALLY UNDER STARTING LOAD WITH SHAFT MISALIGNMENT.

6) Install A New Timing Belt

Install the new timing belt over the timing belt pulleys. Do not pry or use force, loosen the motor mount and/or mounting brackets to loosely install the timing belt.

NEVER PRY ON A TIMING BELT, PRYING THE TIMING BELT WILL DAMAGE THE TIMING BELT PULLEYS TEETH AND/OR FLANGE THAT YOU ARE LEVERAGING AGAINST.

NEVER FORCE ON A TIMING BELT THAT WILL JUST FIT. PRYING THE TIMING BELT ON WILL CRACK THE TENSILE CORD MEMBERS INSIDE THE TIMING BELT.

7) Pre-Tensioning/Final Tensioning

Proper tensioning cannot be stressed enough, to loose of tensioning will cause the timing belt to ratchet (tooth jumping), while too tight of tensioning will possibly cause damage to the bearings, shafts and other drive components besides dramatically reducing timing belt life. The correct timing belt tension is the lowest tension at which timing belts will transmit the required mechanical power and not ratchet teeth when the drive is under a full load.

Loose timing belt tensioning acts like a loosely-held piece of string, with a snapping action as in a high torque situation the string or timing belt will break because the added stress is more than the timing belt was designed to take. While a taut string or timing belt can stand a strong pull.

Take up any loose slack in the timing belt by adjusting the center to center distance between the two timing belt pulleys. Before any final tensioning is to be applied make sure that the timing belt teeth are fully seated in the tooth grooves on both timing belt pulleys. Check to make sure that the timing belt teeth stay seated in the tooth grooves by rotating the drive system by hand. After the pre-tensioning steps are completed there are several methods for verifying proper final tensioning.

Numerical Method (Force/Deflection)

By measuring the deflection of the timing belt with a known force the required tension can be applied. While being a relatively quick method, this method is usually not very accurate. Primarily due to the difficulty in measuring small deflections and forces common in small timing belt drives. This method is better suited for larger drives with long belt spans.

F = Deflection Force

F = Deflection Force

q = Deflection, 1/64" per inch of span length

c = Center Distance

D = Large Pulley Pitch Diameter

d = Small Pulley Pitch Diameter

P = Span Length

Sonic Tension Meter

The sonic tension meter provides the most accurate tension measuring available. Timing belts, like string, vibrate at a particular natural frequency based on mass and span length. By measuring this natural frequency of a free stationary timing belt span the sonic tension meter is able to instantly compute the static timing belt tension based upon the timing belt span length, timing belt width and timing belt type. The sonic tension meter provides accurate and repeatable tension measurements while using a nonintrusive procedure, the measurement process itself doesn't change the belt span tension. Measurement is made by strumming the timing belt like a guitar string to make it vibrate and then hold the meter close to the resonating timing belt to take a measurement.

The sonic tension meter provides the most accurate tension measuring available. Timing belts, like string, vibrate at a particular natural frequency based on mass and span length. By measuring this natural frequency of a free stationary timing belt span the sonic tension meter is able to instantly compute the static timing belt tension based upon the timing belt span length, timing belt width and timing belt type. The sonic tension meter provides accurate and repeatable tension measurements while using a nonintrusive procedure, the measurement process itself doesn't change the belt span tension. Measurement is made by strumming the timing belt like a guitar string to make it vibrate and then hold the meter close to the resonating timing belt to take a measurement.

Both of the tensioning methods above require calculations to arrive at the proper tension value. Since time is of the essence in any project, I will not consume your time with details on how to manually calculate the required tensioning values. A tool that I find extremely valuable in both mechanical power transmission design and also in calculating timing belt tensions is ContiTech – Mechanical Power Transmission Drive Design Calculator. This computer based program is an extremely valuable tool to add to your collection, and the best thing about it is that it's free. This program can be found on the Continental ContiTech website and/or through a link on the Pfeifer Industries website under the Technical section.

Both of the tensioning methods above require calculations to arrive at the proper tension value. Since time is of the essence in any project, I will not consume your time with details on how to manually calculate the required tensioning values. A tool that I find extremely valuable in both mechanical power transmission design and also in calculating timing belt tensions is ContiTech – Mechanical Power Transmission Drive Design Calculator. This computer based program is an extremely valuable tool to add to your collection, and the best thing about it is that it's free. This program can be found on the Continental ContiTech website and/or through a link on the Pfeifer Industries website under the Technical section.

Not to be out done by its competitors the other timing belt manufacturers also offer a similar program for calculating the proper tension value.

NOTE: DUE TO THE HIGH RESISTANCE TO ELONGATION (STRETCH), THERE IS NO NEED TO RE-TENSION A TIMING BELT AFTER THE INITIAL TENSIONING.

8) Final Tightening of Mounting Bolts

Securely tighten all mounting bolts related to the drive components for timing belt tensioning. Loose mounting bolts will cause a change in the center to center distance resulting in performance problems.

9) Start-up

Start-up the drive and observe the mechanical power transmission system. Pay particular attention to any unusual noise or vibration. Shut down the system and check the bearings and motor related to the mechanical power transmission system for excessive heat. If the bearings or motor feel hot, belt tension may be too tight or bearings may be misaligned or not lubricated correctly.