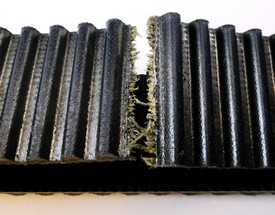

Timing Belt Tensile Break

The two (2) common forms of timing belt tensile break are:

- Crimp style

- Severe shock loads

Crimp Style – Timing Belt Tensile Break

A crimp style timing belt failure often resembles a “straight tear”. A straight tear failure like this may occur when timing belt tensile cords are bent around an excessively small timing belt pulley diameter. A sharp bend may result in large compressive forces within the tensile cords causing individual fibers to buckle or crimp, reducing the overall ultimate tensile strength of the timing belt. Timing belt crimping damage is most commonly associated with:

- Timing belt mishandling

- Inadequate belt installation tension

- Sub-minimal sprocket diameters

- Entry of foreign objects within the timing belt drive

Severe Shock Load – Timing Belt Tensile Break

Severe shock loads can result in timing belt tensile breaks with a ragged and uneven appearance. Often this breakage is seen as a “angled tear”. The timing belt teeth engaged in the timing belt pulley at the instant of the shock load may also develop root cracks and/or exhibit tooth shear. If the shock load occurred only once, or was cyclical and repetitious at one specific location around the timing belt, the remaining belt teeth may appear normal. Cracks forming at the tooth roots sometimes move towards the tooth tips. Timing belt teeth containing multiple cracks may then shear, leaving only a portion of the tooth behind. The shock loads generated by the driven equipment may be an inherent part of system operation or may result from an occasional harsh condition such as jamming. If the drive shock loads cannot be eliminated, the timing belt tensile strength may need to be increased or the timing belt drive replaced with a more forgiving V-belt drive system capable of intermittent slip.

Probable Cause:

- Excessive shock load

Corrective Action:

- Check horsepower rating

- Eliminate or control condition

- Redesign drive

Probable Cause:

- Rolling or prying the timing belt over the flange when installing

Corrective Action:

- Follow proper installation procedure

Probable Cause:

- Sub-minimal timing belt pulley diameter

Corrective Action:

- Use correct timing belt pulley diameter

Probable Cause:

- Misalignment

Corrective Action:

- Check parallel and angular alignment of the timing belt pulleys

Probable Cause:

- Too low or high tension

Corrective Action:

- Adjust tension to recommended value

Probable Cause:

- Momentary peak load exceeded design load

Corrective Action:

- Check horsepower rating

- Redesign drive

Probable Cause:

- Wrong timing belt pitch used

Corrective Action:

- Check horsepower rating

- Redesign drive

Probable Cause:

- Improper timing belt handling and storage

Corrective Action:

- Follow proper installation procedure

Probable Cause:

- Weak support structure or mounts

Corrective Action:

- Reinforce structure

Probable Cause:

- To narrow timing belt width

Corrective Action:

- Check horsepower rating

- Replace timing belt pulley

- Redesign drive

- Replace timing belt

Probable Cause:

- Sharp teeth on the timing belt pulley

Corrective Action:

- Replace timing belt pulley

Probable Cause:

- Debris or foreign object in drive

Corrective Action:

- Follow proper installation procedure

Probable Cause:

- Extreme timing belt pulley run-out

Corrective Action:

- Replace timing belt pulley